Provide transparency & maintain device functionality

Transparent Heaters

Transparent heaters prevent dew condensation and accumulation of snowfall and frost to enhance the visibility of cameras, as well as windows and other surfaces that require high transparency

Overview

Transparent heaters take advantage of Geomatec's thin-film technology and know how to prevent dew condensation and accumulation of snowfall and frost on objects that require high transparency, such as cameras and windows. They are perfect for environments that require temperature controlled surfaces.

- Point1Maintain visibility by eliminating dew condensation, accumulation of snowfall and frost

- Point2Maintaining consistent temperature across the entire surface

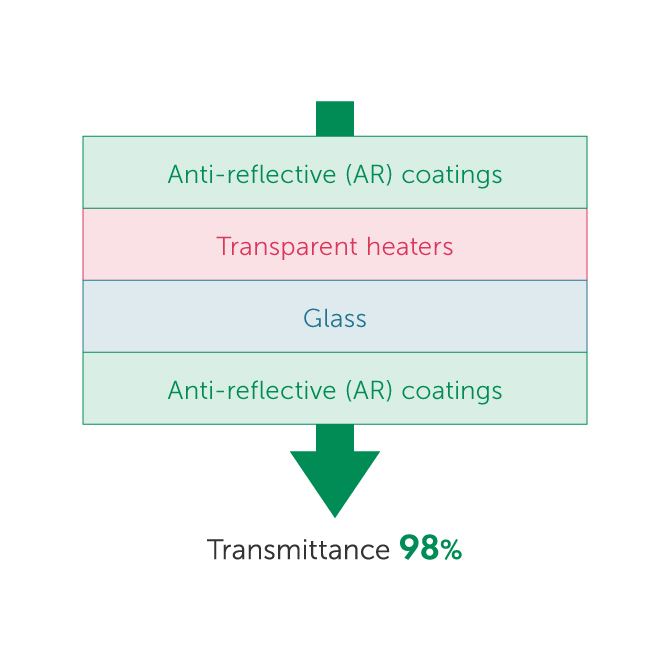

- Point3Clear visibility with a maximum transmittance of over 98%*1

- Point4Applicable to not only flat surfaces but a variety of other forms, including curved and semi-circular surfaces

- Point5Freely customizable to meet conditions such as maximum generated temperatures of 350℃*2

*1When non-alkali glass is used as a substrate material and anti-reflective coating is applied to both sides of the substrate after heater formation (550 nm wavelengths)

*2When using quartz as a substrate

Before & After

An image comparing objects in the same environment with and without transparent heaters applied. Take a look at the clear difference and tangible performance levels.

Evenly heats the entire surface to eliminate visibility flaws

The image on the left is normal glass, while the image on the right is glass with a transparent heater applied and power turned on. This video shows steam blown on the glass from an iron to compare condensation levels. The glass with the transparent heater applied clouds less easily, prevents dew condensation, and maintains clear visibility.

Features & Strengths

Point1 Maintain visibility by eliminating dew condensation, accumulation of snowfall and frost

A transparent heater can be applied to cameras, train windows, and other transparent parts. They are effective at preventing dew condensation, accumulation of snowfall and frost. This helps maintain superior visibility.

-

Visibility clears within seconds after turning the transparent heater on

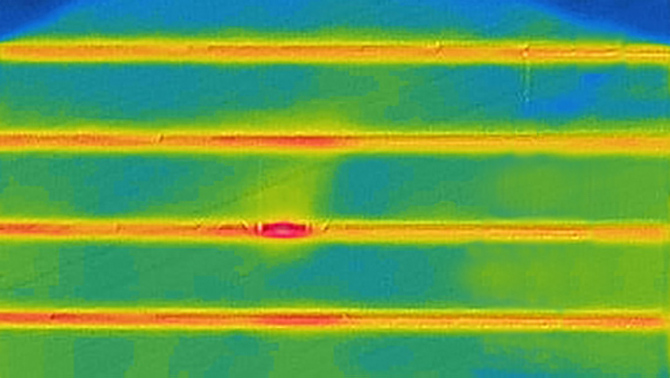

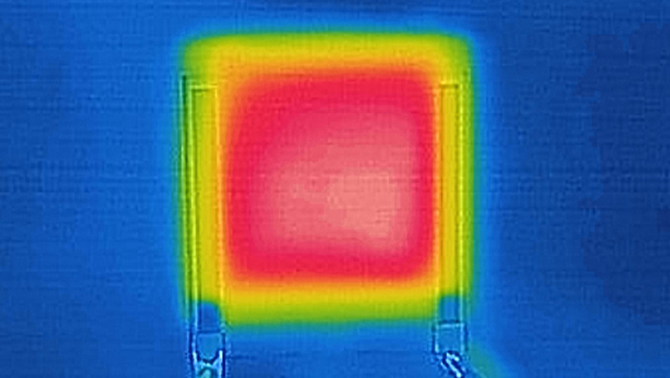

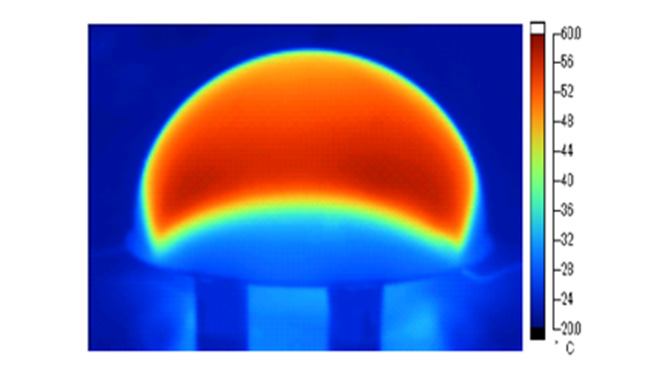

Point2 Maintaining consistent temperature across the entire surface

Transparent heaters maintain a consistent level of heat over the entire object, making them perfect for preserving visibility when transparency is required. They can also be used for the heating stage of microscopes and in medical or biological experiments.

-

With a standard electric heater: heat is generated through wires, resulting in uneven temperatures -

With a transparent heater: even heat generated across the entire surface

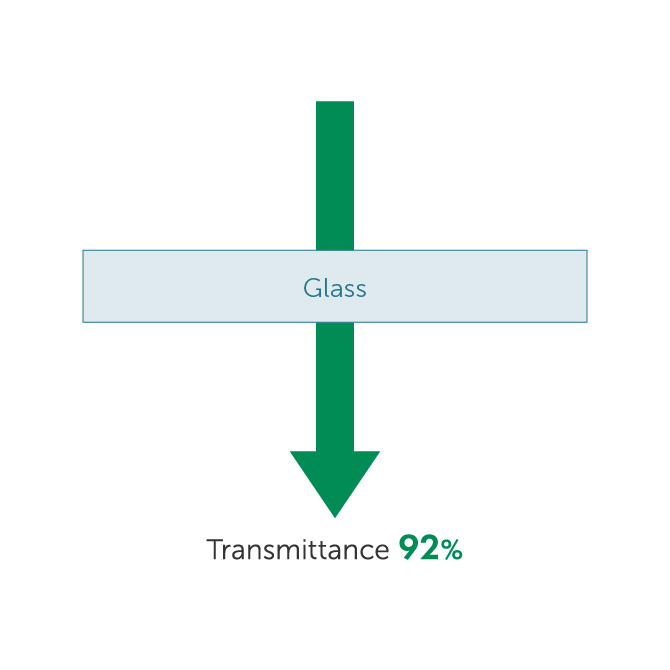

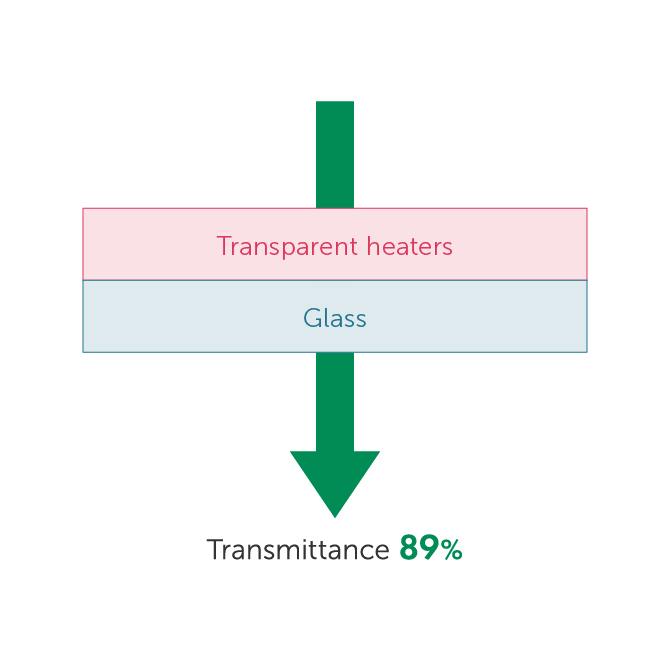

Point3 Clear visibility with a maximum transmittance of more than 98%*1

Transparent heaters can be applied to entire surface of glass and are optimum for use in environments and locations that require transparency. With transparent conductive and ITO films for displays or touch screens, Geomatec has utilized the knowledge gained as a leader in transparency technology to achieve high transmittance rates.

-

Glass only: transmittance of 92%* -

Glass+Transparent heaters: transmittance of 89%* -

Glass + Transparent heater + Anti-reflective coatings (both sides): transmittance of 98%*

*With wavelengths of 550 nm

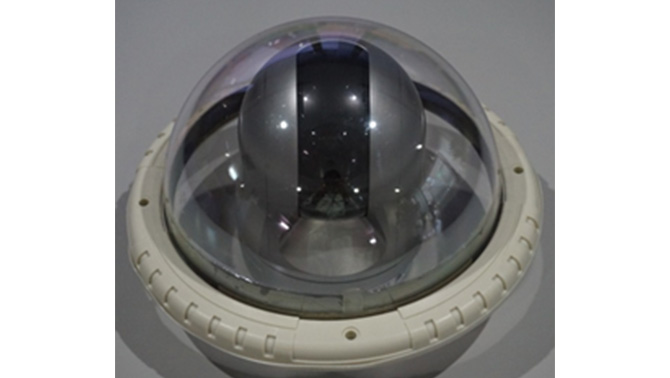

Point4 Applicable to a variety of forms, including curved and domed surfaces

For materials, they can be used with transparent resins, such as glass and poly-carbonate. In addition to flat surfaces, Geomatec can also apply films to curved, domed, and cylindrical (inner and outer) surfaces, as well as other unique shapes, upon consultation. Applicable to a diverse range of needs.

-

Example of transparent heater applied to domed cover -

Thermographic images: even heating of domed surfaces

Point5 Freely customizable to meet conditions such as maximum generated temperatures of 350℃*2

We are capable of meeting various customized demands, specification adjustments upon your request, such as power supply, usage environment, heat generation amount and location, or adding electrodes (bus bar), lead wire and terminal parts, etc. In addition, high-performance thin films such as water repellent coatings and hydrophilic coatings can be combined.

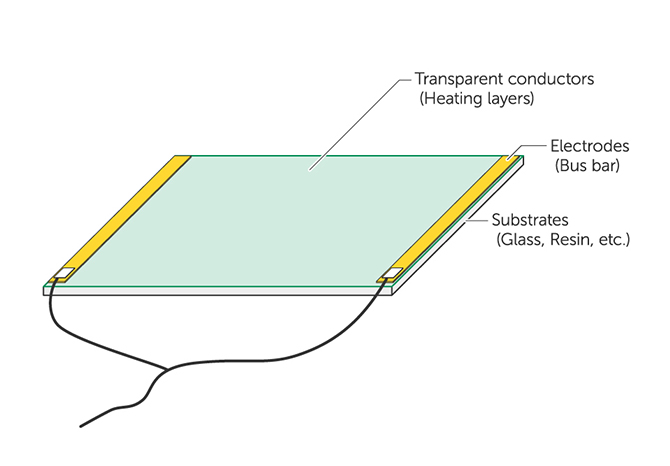

Structures & Mechanisms

Transparent, but heated through electricity

By applying the transparent conductive films and ITO films that are Geomatec's specialty to substrate materials like glass and attaching metal electrodes to conduct electricity, it is possible to create special materials that are transparent and yet generate heat.

Small Lots & Samples

Small Lots & Samples

Small lots and sample items can be purchased via the online store.

Case Study

Applications

Surveillance & Observation Camera Lenses

Obtain solid video records with clear visibility, achieved by preventing dew condensation and accumulation of snow

View more applications

Signal indicators

Prevent snow from accumulating on signal indicators, preserving safe flow of traffic in snowy regions

View more applications

Road guidance system

Making it easier to stay on the road in regions of high snowfall

View more applications

Onboard cameras and sensors

Superior visibility for safe driving in rain or snow

View more applications

Headlights, Fog lights & Rear headlights

Transparent heaters preventing lamp frost

View more applications

Electric train & Railroad car windows

Creating windows that guard against the snow and won't break when struck by icicles

View more applications

Windows

Clear visibility, even in the rainy season or snowy winter

View more applications

Petri dishes & Glass slides for experiments

Thin-film technology that is transparent yet conductive for experiments and observation

View more applications

Microscope heating stage

By combining a transparent heater and temperature sensor to glass in the heating stage, it is possible to adjust the temperature during heating. Since this enables observation during heating, transparent heaters are perfect for medical and biological experiments.

View more applications

Specifications & Data

Manufacturing examples

| Transmittance | Approximately 82% (with wavelengths of 550 nm) |

|---|---|

| Rising temperatures | 30℃ |

| Substrate sizes | 100 x 100 mm (Heated area 96 x 78 mm) |

| Substrate materials | Float glass |

| Substrate thickness | 1.1 mm |

| Energy consumption | 7W (Working voltage 24V) |

Important Notice:Please read before making inquiries

- Please handle with extreme care and attention.

- Although heaters are designed not to heat beyond the rising temperature, we recommend preparing a thermostat, a temperature sensor, and a temperature controller such as a thyristor to control the temperature and the heating time. We also accept requests for customization. Please contact us.

- Please note that it is the user’s responsibility to mount the heater to the intended application.

- Our transparent heater does not have a self-temperature control feature (PTC: Positive Temperature Coefficient).

- We offer mass produced prototype transparent heaters for corporate clients.

- Our transparent heaters are 100% customized to match clients’ requirements.

- When filling out an inquiry form about transparent heaters, we would appreciate it if you could include the information listed alphabetically below. In order to provide a quotation, we require a minimum number of specifications to propose an initial design and to estimate the total cost. From a technical viewpoint, our engineers need these specifications to study feasibility.

- Please notify us in the inquiry if you have a sketch or basic design of the intended product. Sketches or designs can be sent by email following initial inquiry.

Please share the following information with us when sending your inquiry.

- a.Type of substrate material (i.e. float glass, heat-resistant glass, toughened glass, PET, etc.)

- b.Shape & Size of the substrate (width, length, thickness, etc.)

- c.Quantity for initial prototyping and for mass production

- d.Target budget (cost elements: for coating, sourcing substrate and delivery when necessary)

- e.Anticipated time of delivery

- f.Expected time to begin mass production

- g.Application & Usage of heaters (e.g. anti-fogging, defrosting / uniform heating, etc.)

- h.Transmittance

- i.Rising temperature or power consumption - identify temp. before/after heating (i.e. 50℃; from 0℃ to 50℃)

- j.Voltage

- k.Heated area

We appreciate your cooperation and understanding.

Contact us-to-Delivery Process

When outsourcing of thin-film coatings to substrates provided by customers

Below is an example of contact us-to-delivery process when outsourcing of thin-film coatings to substrate materials provided by customers. Whether you need a single item prototype or mass production, trust Geomatec to provide high-quality, high-performance thin-film coatings.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Thin-film manufacturing (procurement, coating and post process)

We will apply thin films to substrate materials provided by customers and carry out high-quality, stable manufacturing and processing in a class 100 to 1,000 clean room (as defined in Federal Standard 209D).

-

Step6Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step7Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

When outsourcing of substrate material procurement and post coating process, in addition to thin-film coating

The following is an example of contact us-to-delivery process when outsourcing of substrate material procurement and post coating process, in addition to thin-film coating. Geomatec will control all steps of the process.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Substrate material procurement

Geomatec will procure glass and film substrates from our trusted supply chain, built over several decades of business.

-

Step6Thin-film coating

We will coat your products with the high-performance thin films necessary to achieve your desired functions.

Our class 100 to 1,000 clean room (as defined in Federal Standard 209D) ensures high quality, stable production. -

Step7Post coating process

We handle post coating process for thin film, including surface splicing of glass and frame printing.

-

Step8Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step9Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

Inquiries & Requests for Materials

Please feel free to contact us for more details.

Detailed specifications and data

Detailed specifications and data Prices and Quotes

Prices and Quotes Delivery Confirmation

Delivery Confirmation Customization

Customization Sample and Prototype Production

Sample and Prototype Production Other

Other

Brochures

Click here to download brochures in PDF format.

Small Lots & Samples

Small lots and sample items can be purchased via the online store.