Feature: Thin Copper (Cu) Film

Overview

Copper has many benefits—it’s easy to process and has excellent electrical and thermal conductivity. Traditionally available in abundance, copper is an essential metal in many industries. However, successive copper mine closures have made future supplies uncertain, at a time when demand is growing continuously for copper materials in renewable energy generation, lithium batteries and in the next generation of power transmission infrastructure, in addition to the copper foil used in lithium batteries, as the world looks to carbon-neutral societies. This has resulted in an increase in copper prices to increase. With copper becoming a ‘precious’ metal, we have developed ways to make effective use of thin copper film.

Typical examples of applications (past accomplishments)

Seed layer (for semiconductors and coatings of electronic parts)

A thin metal layer like this is needed for coating glass and resin substrates.

View more applications (Semiconductors, Electronics & IoT)

Thermal diffusion and thermolysis (electronic parts and power devices)

This method prevents faults and malfunctions caused by heat.

View more applications (Semiconductors, Electronics & IoT)

Ask us about thin metal film coatings for thermal diffusion and thermolysis

Low-reflection blackened electrodes (touch panel)

These can be combined with thin optical films to inhibit reflection of light off metal material surfaces, improving the visibility of screens.

Prevention of electromagnetic waves (electronic devices in aircraft and automobiles)

These coatings prevent communication disturbance and malfunctions caused by electromagnetic waves.

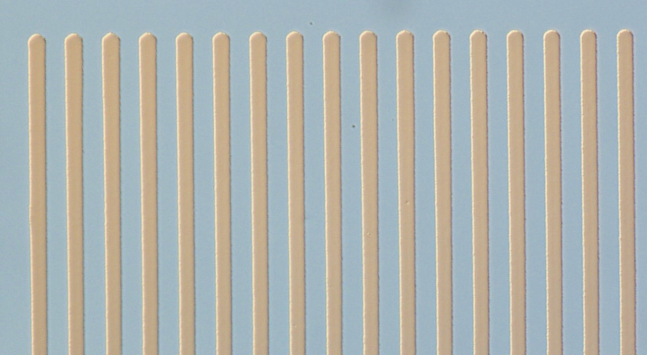

Wiring (various devices)

Easy to process with excellent electrical conductivity.

Thin film processing

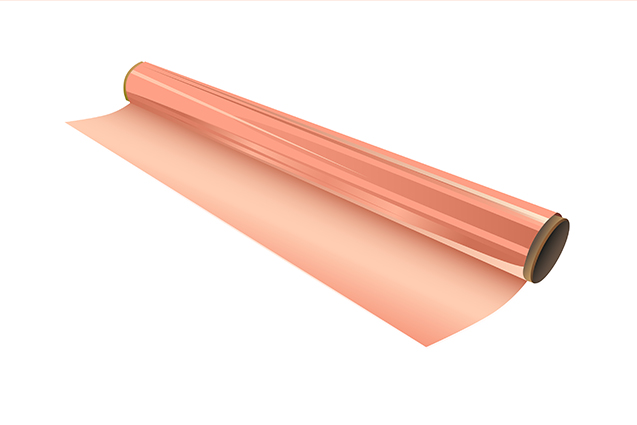

Thin Copper (Cu) Film

- Thickness: Up to 1µm

- Substrate materials: Glass, ceramics, metal, resin, foil, etc.

- Other functions such as an adhesive layer or low-reflection treatment (blackening) can be added.

Rolls

- Up to 1300mm wide

- Maximum length 7000m

- Film thickness From 4.5µm~

- The length that can be created depends on the thickness of the film. Contact us for details.

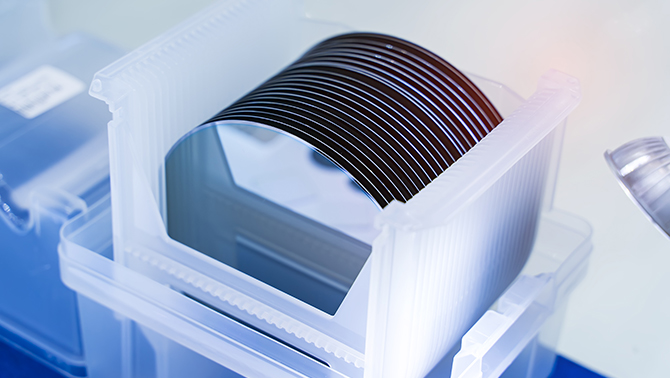

Wafers

- 4”, 6”, 8”, 12”

Sheets

- Up to 1880mm x 1500mm

- The size of a high-volume production line.

Thin film pattern formation processing

- We apply the optimal adhesive layer for the type of base being used and create patterns on the thin copper film and adhesive layer together.

Substrate materials that can be procured

- We can procure these substrate materials:

Soda-lime glasses, non-alkali glasses, aluminosilicate glasses, borosilicate glasses, synthetic silica, Si wafers, PC, PMMA, PET, PEN, TAC, PI, COP, etc. - The sizes that can be procured and created depend on the material. You can also provide your own substrate material. Contact us for details.

Various thin metal films

Thin gold (Au) film

Crystal oscillators (TCXO)

Thin gold film is used for connected and external electrodes. It can be applied by wire bonding or soldering.

Electronics

Thin gold film is used for ridges. Flip chip bonding enables highly reliable joining.

Thin platinum (Pt) film

Fuel cells

Thin platinum film is used as a catalyst in fuel cells, which are expected to be a useful source of clean energy.

Learn more about Metals that can be used as Coating Materials

Inquiries & Requests for Materials

Please feel free to contact us for more details.

Detailed specifications and data

Detailed specifications and data Prices and Quotes

Prices and Quotes Delivery Confirmation

Delivery Confirmation Customization

Customization Sample and Prototype Production

Sample and Prototype Production Other

Other