A method for soldering and brazing of optical and electronic parts

Metallization (for joining)

Overview

A metallized layer is created to join non-metallic materials such as glass or ceramics by soldering or brazing.

Features & Strengths

Point1 The materials and composition of the film can be optimized to suit your purpose

In addition to our standard film composition, we offer customized films to suit your purpose.

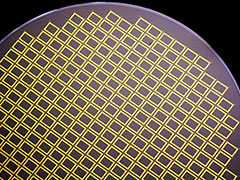

Point2 Fine patterning enables flexibility in the layout

Fine patterning enables a flexible layout on the metallized layer. The metallized layer can be used to create wiring and electrodes.

Point3 Can be combined with functional film

The metallized layer can be combined with various highly functional thin film from GEOMATEC, including anti-reflection film and optical filters.

Applications

Airtight packaging for optical devices

Our metallized layer can be used as a soldering substrate for the window material of airtight packaging for optical devices such as optical sensors, LEDs and semiconductor lasers. Anti-reflection film or an optical filter can also be added.

Wiring and electrodes for electronic devices

Our metallized layer can be used to create solderable wiring and electrodes.

Specifications

| Substrate size | φ8” |

|---|---|

| Film composition | Cr/Ni/Au, Cr/Pt/Au, Ti/Ni/Au, Ti/Pt/Au, etc. |

| Thickness | 0.05µm / 0.2µm / 0.1µm |

| Solder type |

AuSn (gold-tin alloy) *Please note that solder forming is not done by GEOMATEC. We can recommend an affiliated manufacturer if necessary. |

Other specifications may be possible. Please feel free to consult us regarding customization.

Contact us-to-Delivery Process

When outsourcing of thin-film coatings to substrates provided by customers

Below is an example of contact us-to-delivery process when outsourcing of thin-film coatings to substrate materials provided by customers. Whether you need a single item prototype or mass production, trust Geomatec to provide high-quality, high-performance thin-film coatings.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Thin-film manufacturing (procurement, coating and post process)

We will apply thin films to substrate materials provided by customers and carry out high-quality, stable manufacturing and processing in a class 100 to 1,000 clean room (as defined in Federal Standard 209D).

-

Step6Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step7Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

When outsourcing of substrate material procurement and post coating process, in addition to thin-film coating

The following is an example of contact us-to-delivery process when outsourcing of substrate material procurement and post coating process, in addition to thin-film coating. Geomatec will control all steps of the process.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Substrate material procurement

Geomatec will procure glass and film substrates from our trusted supply chain, built over several decades of business.

-

Step6Thin-film coating

We will coat your products with the high-performance thin films necessary to achieve your desired functions.

Our class 100 to 1,000 clean room (as defined in Federal Standard 209D) ensures high quality, stable production. -

Step7Post coating process

We handle post coating process for thin film, including surface splicing of glass and frame printing.

-

Step8Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step9Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

Inquiries & Requests for Materials

Please feel free to contact us for more details.

Detailed specifications and data

Detailed specifications and data Prices and Quotes

Prices and Quotes Delivery Confirmation

Delivery Confirmation Customization

Customization Sample and Prototype Production

Sample and Prototype Production Other

Other